|

|

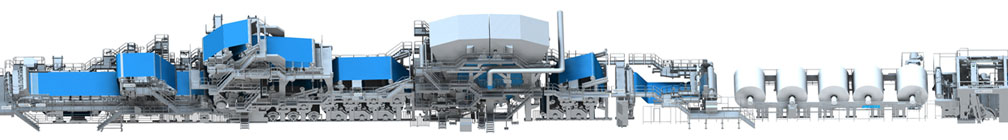

PACKAGED HEAT TRANSFER UNITS Steam/Liquid or Liquid/Liquid. We can design heat exchanger packages and ship as a skid, ready to use. Depending on the media and thermal process details, plated or shell &tube type heat exchangers should be used. In order to achieve efficient, precise and trouble free operation, it is very important to select and size 3 vital equipment of the system. These are heat exchanger, control valve and condensate removal equipment. Selection of them by the same engineering team eliminates undesired poor results of the combination. We have been making our own designs by computerised software. Depending on the fluid properties and temperature program, we are capable to design either plated or shell &tube heat exchangers. We select the type and size of the control valve to obtain precise temperature control and optimum performance between minimum to maximum process loads. Depending on the type of control, we calculate the requested Kvs value of the control valve and we decide the type of the trim. We have options for pneumatic and electric actuators. For steam to liquid applications, we are capable to carry out heat exchanger stall analyse and decide the best suitable condensate removal system. There are float trap, automatic pump trap or condensate pump+trap options for condensate removal. Where the stable temperature programs and very low fluctuations on process loads happen, condensate removal should be achieved by a control valve fitted at the condensate return line. There wonít be a risk of stall in such an application. Additional safety devices and separate control unit have to be added to system in order to eliminate temperature increases at low and zero process load conditions. We design our units depending on our customersí needs and process conditions. After the decision of the type of automation we manufacture and deliver our units as ready to use packaged solution. Benefits of HeatPack packaged units

|

|

Pien Process& Engineering - Head Office Adres : Petrol ›Ģ Mah. Villa Sok. No.23/11 34862 Kartal-Istanbul / Turkey Telefon : +90 216 627 09 97 Mobile 1 : +90 532 320 78 80 Mobile 2 : +90 541 647 22 53 E-mail : pien@pienpro.com |

Copyright © 2020 PienProcess Engineered Efficiency |